A study confirmed that technology plays an essential role in our daily activities as the years go by. We are usually used to doing our household chores such as washing machines, vacuum cleaners, etc. As technology is becoming more developed, we are also more dependent on these technologies such as machines and equipment.

Machines integrate themselves into our daily lives and are playing an essential role in our society. These machines and equipment have an electric shaft motor inside to operate and can find it in household appliances, blowers and pumps, machine tools, power tools, and disk drivers.

Choosing a guaranteed quality for an Electric Shaft Motor needs a thorough evaluation and calculations to ensure that our electric shaft motors are well-built and sustainable with their functions.

-

Table of Contents

How does an electric motor work?

An electrical shaft motor is an electrical engine that changes electrical energy into mechanical energy. There must be a connection between the magnetic field and electric current and will flow in a twisted wire applied on the motor shaft to produce power. Just like an air compressor desiccant dryer, they can be an essential part to factory efficiency.

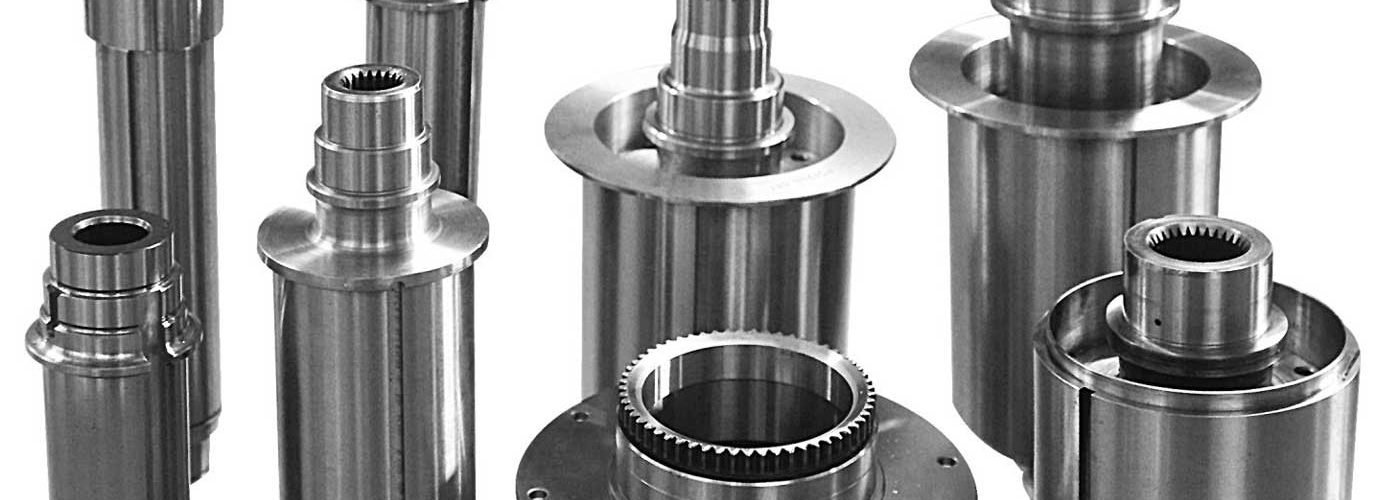

They are specifically used to transmit power to a machine that absorbs energy from the machine which produces power. For an electric shaft motor to work, a cylindrical bar rotating machine inside the motor is called a shaft. The shaft is the key component in most rotating machines such as escalators, washing machines, and electric fans.

Now let’s talk about how the shaft was made of?

The specific design and prototyping of shafts depend and are necessary for all functional appliances. The shaft could be solid or hollow and identified as straight, flexible, cranked, or articulate. The standard shaft used for power transmission is called a straight shaft.

It is generally mold by hot rolling and finished by cold drawing and grinding. The hard mold shaft is stronger than the hot-rolled shaft but with residual stresses. The larger diameter of the post is usually forged and molded straight in a lathe.

When choosing the best material for your electric motor shaft to maximize reliability, you need to consider several considerations. So here we give you things you need to consider before buying Electric Shaft Motor Thailand:

Cost and Material Deficiencies

For ordinary shafts, the materials used are mild steel, and we can use alloy steel such as nickel or chromium-vanadium steel when a shaft is required for high strength. The following are the properties that materials should have to make a shaft:

- High strength suitable

- Good mechanization

- Low-notch sensitivity factor

- Good heat treatment properties

- High wear-resistant properties

Since we already know what materials and properties that it should have.

Types of shafts

- Transmission Shaft

A shaft that transmits power from the source to the machine that absorbs energy is called a transmission shaft. Transmission refers to the whole drivetrain, including gearbox, clutch, and final drive shaft. Any machine that requires to operate with a high rotational speed uses transmission to decrease the engine speed into slower speed and torque to increase the process. It can use in agricultural, industrial, construction, mining, and automotive equipment.

- Machine Shafts

A shaft that is an integral part of a machine itself is called a machine shaft, and can find it inside parts of the machine assembly. A crankshaft is considered a machine shaft if we consider car engines as examples.

- Axle shaft

A non-rotating shaft that is used in a vehicle is called an axle shaft. It is usually explicitly found in cars to support the weights of any car. It is an essential component of your car as the axles are connected to the wheels. For our vehicle to operate, we used the axle shaft as it gives power to the wheels to propel.

- Spindle Shaft

A rotating shaft with a fixture for holding tools or a workpiece is also called a spindle shaft. It serves as a positioner, a rotary drive, and support for a device or workpiece. It is used in different ways to satisfy the requirements. Spindles must reach an extremely high concentric at the increased stiffness and usually medium speeds for turning and grinding. For milling and drilling, spindles are used at high rates under changing conditions.

More

As the electric motor shaft is more environmentally friendly, it doesn’t have burning fossil fuels which produce harmful greenhouse gasses that can cause pollution. Electric motors generally save money over time, whereas gasoline engines are more costly in comparison.

We also need to remember that our machines and equipment also have their limitations. Overuse can cause stress to the electric motor shaft. Some parts of our electric engine might collapse due to the high pressure. We might hear increasing vibrations or be too noisy in operations. These things are expected to happen as we use electric motor shafts.

But don’t you worry, any electric motor shaft expert can expound these few things you have read.

Fortune Cross is one of the best electric shaft suppliers in Bangkok with experts that innovate and enhance our production. We maintain the quality under specified standards. Want to know more about our products? Fortune Cross is here to help you!