In a rapidly evolving technological landscape, the demand for tailored solutions has given rise to the era of custom machines. This article explores the significance of custom machines, delving into their applications, advantages, and the process of designing these bespoke marvels.

Table of Contents

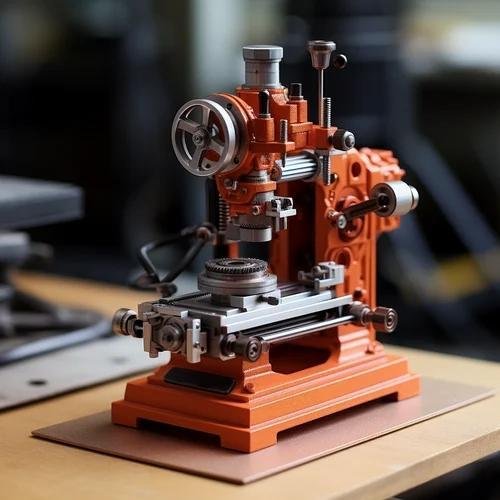

What are custom machines?

Custom machines are uniquely designed mechanical systems created to perform specific tasks or functions within a particular industry or application. These machines are tailored to meet the unique requirements and challenges of a given task, offering a bespoke solution compared to off-the-shelf, standardized machines. Custom machines are developed through a process that involves careful analysis of the intended application, collaboration between engineers and end-users, and a detailed design and manufacturing phase. The goal is to provide a specialized and efficient solution that precisely aligns with the needs of a specific job or process.

How Custom Machines work?

The custom machining depend on their specific design and intended purpose. Here’s a general overview of how they typically work:

Needs Assessment:

The process begins with a thorough understanding of the task or process the custom machine is meant to perform. Engineers and designers work closely with end-users to identify requirements and challenges.

Design Phase:

Based on the needs assessment, engineers create a detailed design for the custom machine. This includes selecting appropriate components, specifying dimensions, and determining the necessary functionalities.

Prototyping:

A prototype of the custom machine is built to test and validate the design. This phase allows for adjustments and refinements before the final production.

Testing and Iteration:

The prototype undergoes rigorous testing to ensure it meets performance standards. Feedback from testing informs any necessary adjustments or modifications to enhance the machine’s efficiency and reliability.

Production and Integration:

Once the design is finalized and the prototype meets the requirements, the custom machine goes into production. Components are manufactured, and the machine is assembled. It’s then integrated into the existing workflow or system. These are essential to keep the custom machine in optimal condition. This ensures longevity and continued reliability in its performance.

Adaptability:

Depending on the design, custom machines may be equipped with features that allow for adaptability to changing requirements. This flexibility ensures that they remain effective even as needs evolve.

Applications Across Industries

Custom CNC machines find applications across a wide range of industries, offering tailored solutions to address specific challenges and optimize processes. Here are some notable applications:

Healthcare:

In the healthcare sector, custom machines are utilized for specialized medical equipment manufacturing, diagnostic processes, and tasks that require precision and reliability

Agriculture:

Custom machines are employed in agriculture for tasks like planting, harvesting, and processing crops. These machines can be designed to suit the unique requirements of different crops and farming practices.

Food and Beverage:

In food processing, custom machines can be designed for tasks such as sorting, packaging, and quality control, ensuring compliance with specific industry standards

Pharmaceuticals:

Custom machines play a vital role in pharmaceutical manufacturing, contributing to processes like pill packaging, dosage formulation, and quality assurance

Energy :

Within the energy sector, custom machines are employed for tasks like component fabrication, maintenance of specialized equipment, and optimizing processes in power generation.

Real world examples

Tesla’s Giga factories:

Tesla, the electric car manufacturer, has implemented custom machines in their Giga factories to automate and optimize the production of electric vehicles. Custom robotic systems handle tasks such as battery assembly and vehicle manufacturing, contributing to Tesla’s ability to scale production efficiently.

NASA’s Robotic Exploration:

NASA employs custom robotic systems for space exploration. For example, the Mars rovers (e.g., Spirit, Opportunity, Curiosity) are equipped with custom-designed tools and instruments to analyze the Martian surface.

Boeing’s Aircraft Manufacturing:

Boeing utilizes custom machines in the manufacturing of aircraft components. Automated systems, such as robotic arms and precision machining tools, are customized to ensure the accuracy and efficiency required in the production of complex aerospace components.

Medical Device Manufacturing by Medtronic:

Medtronic, a medical technology company, employs custom machines in the manufacturing of medical devices. Customized robotic systems are used for tasks such as precision assembly and packaging of medical implants, contributing to the quality and consistency of their products.

Automated Warehousing by Amazon:

Amazon utilizes custom machines in their fulfillment centers for tasks such as sorting, packaging, and shipping. Customized robotic systems, like Amazon’s Kiva robots, optimize the warehouse operations, leading to faster order processing and delivery.

These real-world examples highlight how organizations across different industries leverage custom machines to enhance efficiency, precision, and innovation in their respective fields. Customized solutions contribute to improved processes, increased productivity, and the ability to address unique challenges in various sectors

How to design Custom Machines ?

Designing custom machines involves a systematic process to ensure that the final product meets the specific requirements and challenges of its intended application. Here are the key steps involved in designing custom

Conceptualization and Ideation:

Brainstorm and develop conceptual ideas for the machine based on the identified needs. Consider factors such as size, capacity, materials, and required functionalities.

Engage with end-users to understand the specific tasks the custom machine needs to perform, as well as any unique challenges or constraints.

Testing and Validation:

Conduct thorough testing of the prototype to ensure it meets performance standards and addresses the identified needs. Gather feedback from testing for further improvements. Based on the feedback from testing, iterate on the design to refine and optimize the custom machine. This may involve multiple rounds of prototyping and testing.

Materials Selection:

Choose materials for construction that align with the performance requirements, durability, and any industry-specific standards. Develop detailed manufacturing plans, including processes, assembly procedures, and quality

Documentation:

Create comprehensive documentation that includes assembly instructions, maintenance procedures, and any troubleshooting guidelines. This documentation is essential for future reference. Develop training programs for end-users to ensure they can operate and maintain the custom machine effectively.

Finalization and Production:

Finalize the design based on feedback and testing results. Once approved, move into full-scale production of the custom machine Implement quality assurance processes to monitor and control the manufacturing process, ensuring that each unit meets the specified standards.

The successful design of custom machines requires a collaborative and iterative approach, involving input from various stakeholders throughout the process. Each step contributes to creating a specialized solution that meets the unique requirements of its intended application.

Challenges And Considerations in Custom Machines

Balancing Customization with Standardization:

Striking the right balance between creating a custom solution and maintaining some level of standardization can be challenging. Over-customization may lead to higher costs and complexity. Designing and building custom machines can be expensive. Organizations need to carefully consider budget constraints and weigh the initial costs against long-term benefits.

Skill and Expertise Requirements:

Developing custom machines demands specialized knowledge and skills. A shortage of skilled professionals can be a challenge in ensuring successful design and implementation. – Ensuring that end-users are trained to operate and maintain custom machines is crucial. Resistance to change or inadequate training can hinder successful implementation.

Integration with Existing Systems:

Integrating custom machines with existing workflows or systems can be complex. Compatibility issues may arise, requiring careful planning and coordination.

Regulatory Compliance:

Adhering to industry regulations and standards poses a challenge. Custom machines must meet legal requirements, and failure to comply can lead to delays and additional costs. Despite thorough planning, unexpected challenges may arise during the design phase, requiring adjustments and potentially impacting timelines.

Scalability:

Custom machines may face challenges when scaling up production. Adapting to increased demand or changes in the scale of operations requires careful consideration during the design phase.

Maintenance and Support:

Developing a robust maintenance plan and ensuring timely support for custom machines is essential. Lack of maintenance can lead to downtime and increased operational

Market Dynamics:

Changes in market conditions and industry trends may impact the relevance and effectiveness of custom machines. Staying abreast of market dynamics is crucial for continued success.

Despite these challenges, careful planning, collaboration, and a thorough understanding of industry needs can help organizations navigate the complexities of custom machine development successfully.

Advantages Of Custom Machines

The advantages of custom machines lie in their ability to provide tailored solutions to specific challenges and tasks within various industries.

Increased Productivity:

The specificity of custom machines contributes to enhanced productivity by streamlining processes and minimizing downtime. Custom machines can incorporate advanced control systems for quality assurance, contributing to the production of high-quality goods

Safety and Ergonomics:

Designing machines with the specific user in mind allows for considerations of safety features and ergonomic considerations, creating a safer working environment Industries with unique or specialized requirements benefit from custom machines that can address specific challenges that standard machines may not handle effectively.

Reduced Environmental Impact:

Custom machines can be optimized for resource efficiency, contributing to sustainable practices and reducing the environmental impact of operations .

Streamlined Workflows:

By aligning with the workflow and specific needs of the industry, custom machines contribute to streamlined processes, reducing bottlenecks and improving overall efficiency .The careful design and testing process of custom machines often result in durable and reliable systems, leading to longer equipment lifespan

Innovation:

Custom machines enable companies to innovate and stay ahead of the curve by incorporating the latest technologies and methodologies into their process.

Future Trends

Future Trends of Custom Machines in AI:

Custom machines are set to embrace the power of AI, becoming even smarter and more adaptable. Imagine machines that can learn and make decisions on their own! This means they’ll be able to handle tasks more intelligently, optimizing processes and improving efficiency. The future holds a w world where custom machines, infused with AI, become indispensable tools, revolutionizing how industries operate.

Promoting Environmentally Friendly Practices:

Custom machines are gearing up to be eco-friendly champions. Think of machines designed not just for performance but also with a green heart. They’ll be more energy-efficient, produce less waste, and contribute to sustainable practices. Picture a future where custom machines not only get the job done but also do it in a way that’s friendly to our planet. It’s a step towards a greener, cleaner, and more responsible future.

FAQs

Why choose custom machines over off-the-shelf solutions?

Custom machines offer personalized solutions, optimizing efficiency and performance for specific tasks. They provide a competitive edge by addressing unique challenges that off-the-shelf solutions might not tackle effectively.

What challenges are associated with custom machine development?

Challenges include finding the right balance between customization and standardization, addressing technological obsolescence, managing costs, ensuring regulatory compliance, and integrating custom machines with existing systems.

How do custom machines contribute to environmental sustainability?

Custom machines can be designed with environmentally friendly practices in mind, focusing on energy efficiency, reduced waste, and sustainable materials. This contributes to a greener approach to industrial processes.

How can companies ensure the success of custom machine implementation?

Success involves careful needs assessment, collaboration between stakeholders, adherence to industry standards, thorough testing, user training, and ongoing support. Companies should also consider the scalability and adaptability of custom machines.

Are custom machines more expensive than standard machines?

While the initial costs of custom machines may be higher, they often lead to long-term cost savings by improving efficiency, reducing operational costs, and offering a tailored solution that aligns with specific needs.

How do custom machines impact productivity in industries?

Custom machines significantly enhance productivity by streamlining processes, improving efficiency, and addressing specific challenges within industries. Their tailored design allows for optimized performance, contributing to increased productivity and positive outcomes.

In conclusion, the transformative impact of custom machines is evident in their ability to optimize performance, increase productivity, and foster sustainable practices. Their future promises even greater strides with the integration of artificial intelligence, ushering in a new era of intelligent, learning machines that adapt seamlessly to evolving needs.