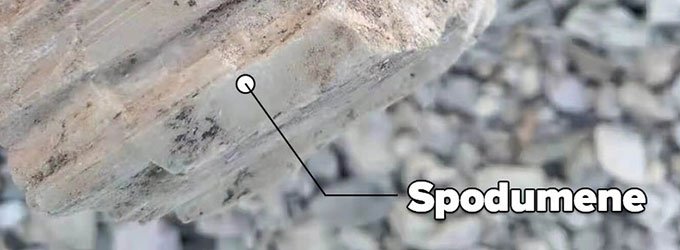

The rapid development of new energy vehicles has changed the consumption structure of lithium resources and also stimulated the demand for spodumene. How to process spodumene? We will tell you about beneficiation methods and machines.

Table of Contents

Spodumene is in great demand

Spodumene is one of the main lithium-containing minerals, also known as type 2 spodumene. Industrial processing of spodumene can be widely used in the lithium chemical industry, glass, ceramics, and other industries.

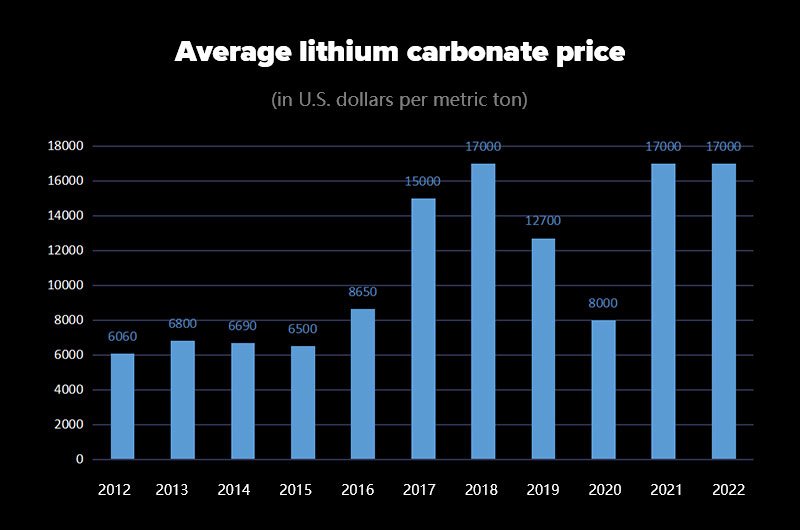

According to relevant research, by 2025, the total global lithium demand can reach 1.373 million tons. The rise of the new energy market has driven the growth of lithium metal demand and the price of spodumene concentrate.

In the development of lithium ore resources, it is particularly important to choose the correct spodumene process. If the ore plant wants to develop spodumene, what kind of beneficiation method and equipment is needed?

1. Hand-selected spodumene

Before the spodumene formally enters the sorting process, it is generally hand-selected for preliminary screening and pre-selection. After crushing (the width of ore grains is ≤ 1200mm), the ore is sent to the manual selection belt, and the appearance color and gloss are determined. Select 25~300mm spodumene.

Equipment: Crusher (jaw crusher), belt conveyor, screening machine

2. Spodumene desliming

Desliming in advance is mainly to carry out a desliming and impurity removal operation before sorting. The crushed minerals are hand-selected into a ball mill for grinding to -0.074mm, and then dodecyl amine or coconut oil amine is used as gangue mineral capture. Collecting agent and flotation to remove slime and mica.

Equipment: Overflow ball mill

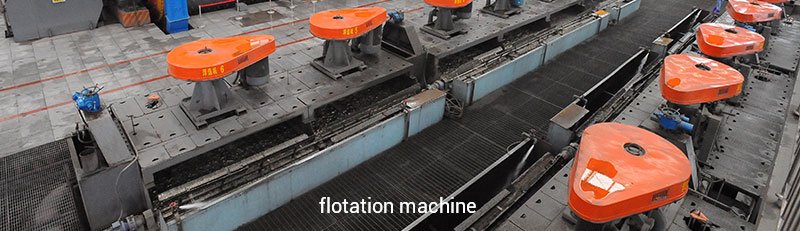

3. Spodumene flotation

There are two methods of spodumene flotation: positive flotation and reverse flotation. Among them, positive flotation is to add oleic acid and its soap salts as collectors in a strongly alkaline environment to directly float spodumene. Reverse flotation is to adjust the alkaline environment with lime first, then add dextrin, starch, etc. to inhibit spodumene, and float out silicate gangue ore.

Equipment: Flotation machine, chemical mixing tank

4. Dense media separation of spodumene

Spodumene with finer particle sizes can be separated by the dense medium separation method. According to the density difference between minerals, the pressure of 0.05-0.20Mpa is used to enter the dense medium cyclone for separation, and the bottom flow part is lithium pyroxene.

Equipment: Dense medium cyclone

5. Magnetic separation of spodumene

When spodumene contains iron impurity minerals, magnetic separation is required for iron removal. Because most of the associated iron impurities are weak magnetic beneficiation, it is necessary to remove iron through strong magnetic equipment to obtain spodumene concentrate with low iron content. Spodumene often contains feldspar, and feldspar concentrate can be obtained by magnetic separation.

Equipment: High gradient magnetic separator

6. Combined beneficiation of spodumene

When the above-mentioned single beneficiation method cannot obtain high-grade spodumene concentrate, a combined beneficiation method is required for effective separation. Common combined processes include flotation-magnetic separation combined process, flotation-gravity separation-magnetic separation combined process, flotation-chemical treatment combined process, etc.

Equipment: Flotation machine, magnetic separator, jig, shaker, spiral chute, etc.

The above is the introduction to the spodumene beneficiation process, which is for reference only. The specific detailed process design and equipment layout should be determined according to the characteristics of the ore itself.